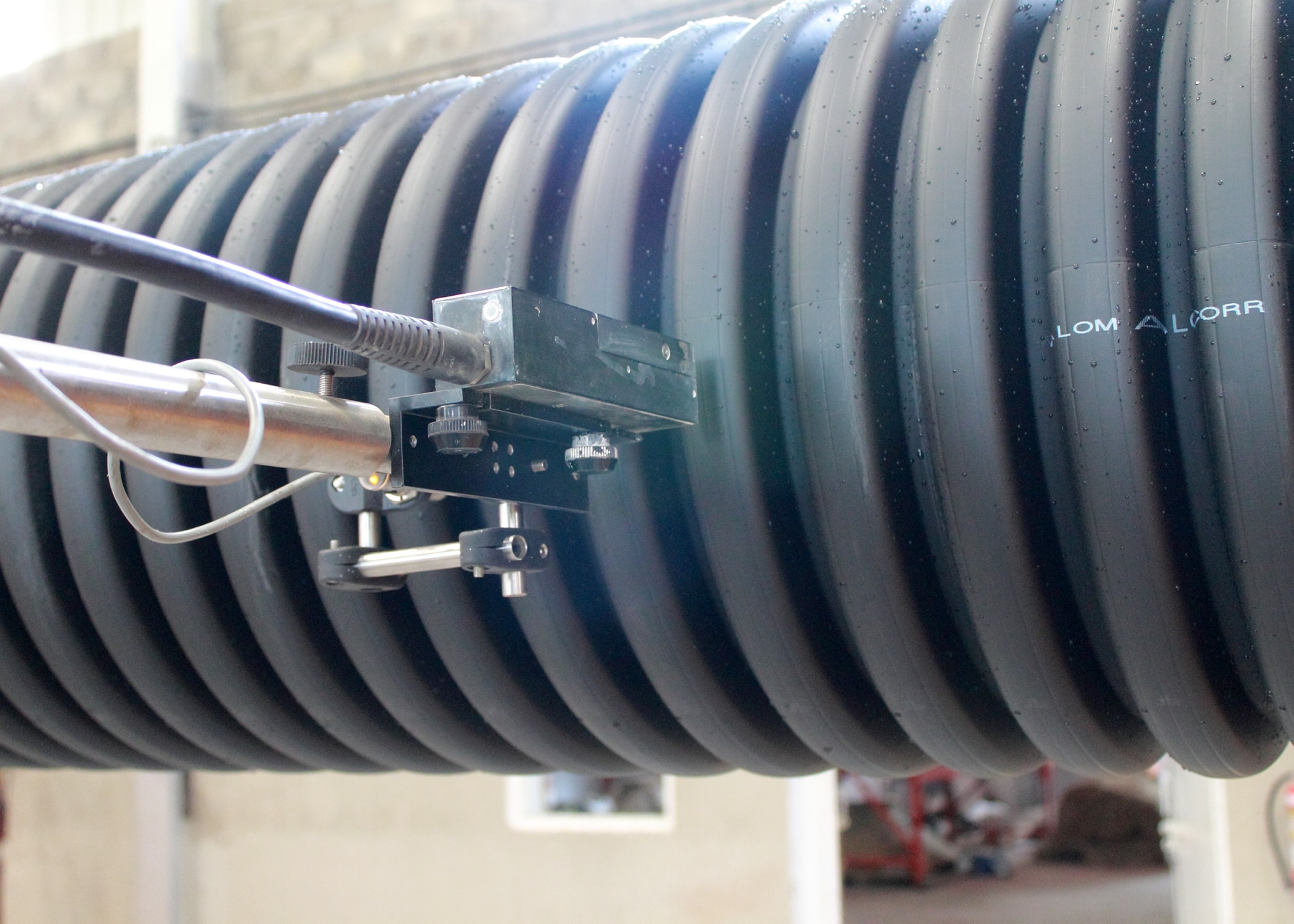

About Alcorr

Alcorr pipes feature a Double Wall Corrugated (DWC) profile constructed from high-density polyethylene (HDPE) material. These pipes are certified in accordance with IS 16098 (Part 2) standards. The design includes an external layer with annular corrugation and a smooth internal surface, contributing to their high structural integrity.

The chemical and biological inertness of Alcorr pipes, combined with their metallurgical advantages, ensures an extended service life and superior hydraulic performance. These attributes, along with significant social and environmental benefits, position Alcorr pipes as the optimal choice for underground gravity flow applications, offering substantial techno-commercial viability.

For the past four decades, Double Wall Corrugated (DWC) polyethylene (PE) pipes have been utilized worldwide to develop efficient wastewater collection and conveyance networks. Alcorr pipes are produced using advanced technology from high end machinery with the longest experience in the industry.

Alcorr pipes are designed for non-pressure underground applications, including sewerage, drainage, cross drainage (pipe culverts), gravity flow irrigation, and stormwater storage, and for storage and diversion of water for waterlogging prone cities. Alcorr pipes help Urban local bodies, departments, and construction companies, housing, and new factories compounds to manage their wastewater, sewage, slurry, and rainwater problems efficiently. Underground gravity flow for irrigation is also a prevalent use.

Alom Poly has one of the largest production capacities in Asia for DWC and HDPE pipes which are continuously increasing and improving in scope and volumes.

Mechanical Characteristics For Alcorr Pipes:

Constituent of IS 16098 (Part 2). Testing standards for individual characteristics:

| Characteristics | Reference of IS Standards |

|---|---|

| Ring Flexibility | IS 16098 (Part 1) : 2013 : Annex D |

| Ring Stiffness | IS 16098 (Part 1) : 2013 : Annex C |

| Creep Ratio | IS 16098 (Part 1) : 2013 : Annex E |

| Impact Strength | IS 12235 (Part 9) |

Available Sizes:

| Sl. No. | Nominal Internal Diameter (mm) | Outer Diameter (mm) | Stiffness Class | Standard |

|---|---|---|---|---|

| 1 | 75 | 90 | SN 4 | IS 16098 (Part 2) |

| 2 | 100 | 120 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 3 | 135 | 160 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 4 | 150 | 180 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 5 | 170 | 200 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 6 | 200 | 238 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 7 | 250 | 290 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 8 | 300 | 345 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 9 | 400 | 480 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 10 | 500 | 580 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 11 | 600 | 715 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 12 | 800 | 955 | SN 4 and SN 8 | IS 16098 (Part 2) |

| 13 | 1000 | 1200 | SN 4 and SN 8 | IS 16098 (Part 2) |

Our products are typically manufactured in standard lengths of 6 meters. However, they can be customized in lengths of 3, 9, or 12 meters to meet specific project requirements. We also offer pipes with a stiffness class of SN 16. Specialised features such as anti-rodent protection and flame retardant properties are also available upon request.

Ease in Handling and Transportation

Light weight permits simple manual haulage of the pipes from a distant stockyard to remote locations where trucking is not possible.

Our NetworkWhy Alcorr Double Wall Corrugated (DWC)?

- Environmentally safe

No leaks, no cracks and no damage to environment and soil - Socio-environmental friendliness

Pipe laying does not disturb urban clusters - Long Lasting

Service life of over 100 years - Cost effective

Uses minimal material for equal strength - Ease of Installation

Uses fewer manpower and can be installed in very constrained locations - Chemical Resistance

Chemically inert to waste water ingredients and ‘crown corrosion’ is non-existent - Green piping material for environmental sustainability

Download Environment Friendly – whitepaper

Alcorr Applications

- City and urban clusters

Economical, easier and swifter installation, handling and transportation to overcome socio-environmental issues with underground pipe installations. - Urban sewerage rehabilitation

Economically most viable in crowded and haphazardly grown old core clusters of the city - Highway and busy roads

Anti leakage coupling to create environment friendly and virtually maintenance free drainage corridors - Earthquake prone areas with high tectonic movements – high strength to weight ratio and adaptation of pipe length and roundness to uneven ground or earth movements.

- Rainwater drainage

(agricultural, highway and citywide) - Shallow and deep tube – well casing

- Effluents disposal and Industrial drainage