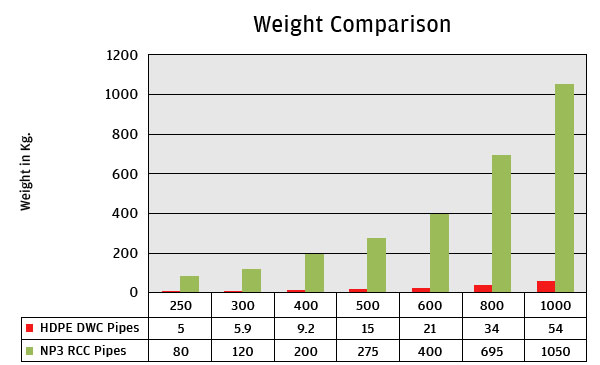

Alcorr Double Wall Corrugated (DWC) HDPE pipes are economically viable for its high strength-to-weight ratio, long metallurgical life expectancy, structural integrity, hydraulic capability, favourable chemical properties and socio-environmental benefits (saving enormous time for project implementations). Higher flexibility and flexural strength ensures its capability to sustain greater overburden as well as live load impact. DWC pipes save around 50 – 65% of total costs for raw material in comparison to solid wall plastic pipes and are far lighter in weight as well.

| Comparison of DWC HDPE Vis-à-Vis Non Pressure RCC pipes | ||

|---|---|---|

| Pipe Property | HDPE Double Wall Corrugated Pipe | Concrete Pipes |

| Metallurgical Property | Flexible pipe – good flexural strength, high tenacity, not brittle | Rigid Pipe – No Flexibility, high density, low tenacity, very brittle |

| Structural Property | Flexible Joints – allows deformation and movement that won’t damage structure under external load. No additional structural protections in the form of bedding reinforcements are necessary. | When bearing external load, even very small deformation will damage the structure of pipe. Provision of additional structural bedding is almost imperative. |

| Hydraulic Properties | The glass smooth inner surface has Manning’s ‘N’ in the range of 0.009-0.011 which virtually doesn’t deteriorate during the entire life expectancy. | The flow resistance factor for NP RC Pipes is much higher (0.011 – 0. 015) which also deteriorates very fast in 5 year ageing intervals as well. |

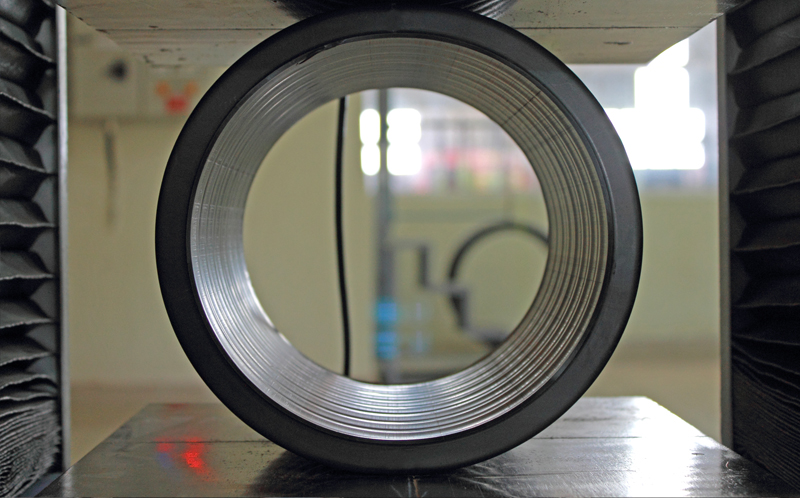

| Jointing System | Online Integrated Coupling system with electrometric seal ring for leak tight joints | Spigot & socket joints & sealing by cement mortar, additional coupling material required |

| Water Tightness | Very good connection tightness, no leakage of sewage & no infiltration of ground water even in unfavorable bedding contour. Environmentally friendly since no chance of water & soil pollution. | Poor tightness, susceptible to leakage at joints, no flexibility for bending compatibility with bed contour. Possibility of environmental pollution due to sewage leakage |

| Chemical Inertness | Immune to all corrosive chemicals and biological ingredients. No possibility of ‘Crown Corrosion’ | Deteriorates rapidly in contact with mild chemicals and biological contents. ‘Crown Corrosion’ is a chronic problem resulting in frequent system maintenance problems. |

| Life Expectancy | Designed Life Time expected up to 75 – 100 years. Time tested up to 40 years in various parts of world. | Maximum life not more than 30 years |

| Socio-environmental aspects | The installation time for the deep underground facilities is directly linked with the degree of discomfort of city dwellers. DWC HDPE pipes being very light are far easier and economical to handle, transport, install and maintain and is therefore considered as the best system to overcome the cited socio-environmental bottleneck. | On account of heaviness, susceptibility to damage during transportation and handling, imperative usage of crude and space consuming tools in installation process, excessive requirement of manpower in the installation process does not make RCC Pipes appropriate especially in core urban clusters. |

| Installation time | Good flexibility, minimal requirement of foundation, no seasonal or temporal constraints in installations, good bending & flexural property, light weight, ease in transportation, handling and installation results in a favourably low installation time. | High rigidity, imperative requirement for structural bedding, cumbersome and intensive labour oriented transportation & handling, extensive requirement of equipments for lowering & installation. |

| Available lengths | Available in 6 (Six) Meter Standard lengths. Can be cut to any length by simple hand tools. Length can also be customized as per requirement. | Available in 2.5 meters lengths only. Cannot be reduced to shorter lengths by simple cutting at site. |

| Transportation & Handling | Due to light weight and flexibility, chance of damage during handling & transportation is negligible. Easy to ensure closed end water test at field after installation. | Highly susceptible to damage during transportation & handling. Once damaged, repair may not be at all possible. Almost impossible to ensure the closed end continuity test at field after laying which is an imperative necessity for gravity flow systems. |

| Maintenance Status | Because of favourable chemical and biological properties in relation to resistance to corrosion, incrustation and anti-scale formation, there is virtually no need for maintenance. Periodical pressure flushing will keep the inner surface of the pipe glass smooth for its entire life. | Considerable quantum of annual maintenance budget allocation is necessary to keep the system working. Conveyance capability would reach the bottom at the end of its 30 year design life. |

| Summary |

DWC HDPE Pipes are economically & technically more reliable than NP3 RC Pipes. All features taken into consideration, the DWC HDPE Pipes will be significantly cheaper and less time consuming to complete a total project in comparison to Non-Pressure Concrete Pipes. | |

For Additional technical details please visit